- Home

- Products

- Dry Feeding Series

- Integrated Suction Machine

Product Categories

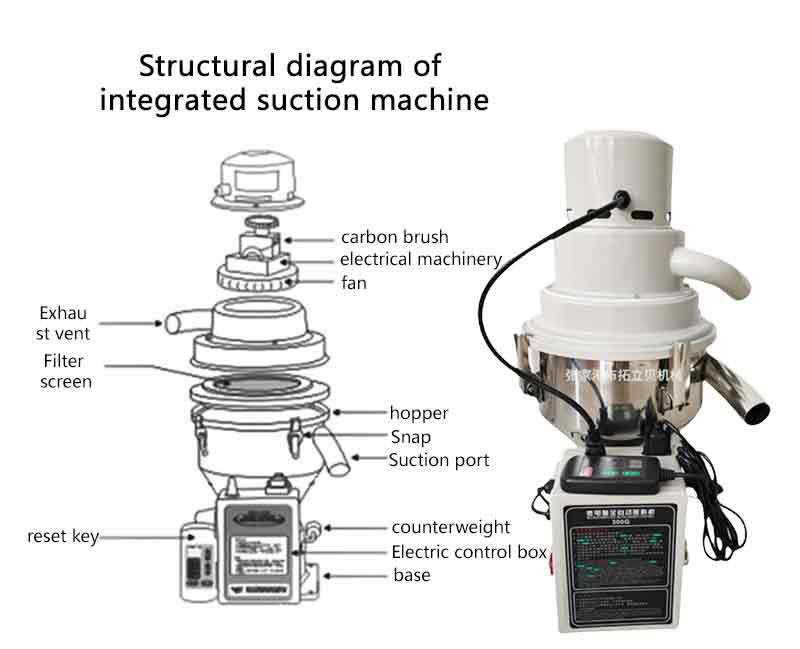

Integrated Suction Machine

product description

Product features

Electronic pulse back blowing function, electronic dust removal, no need for manual cleaning.

Efficient and energy-saving, not easily clogged or damaged.

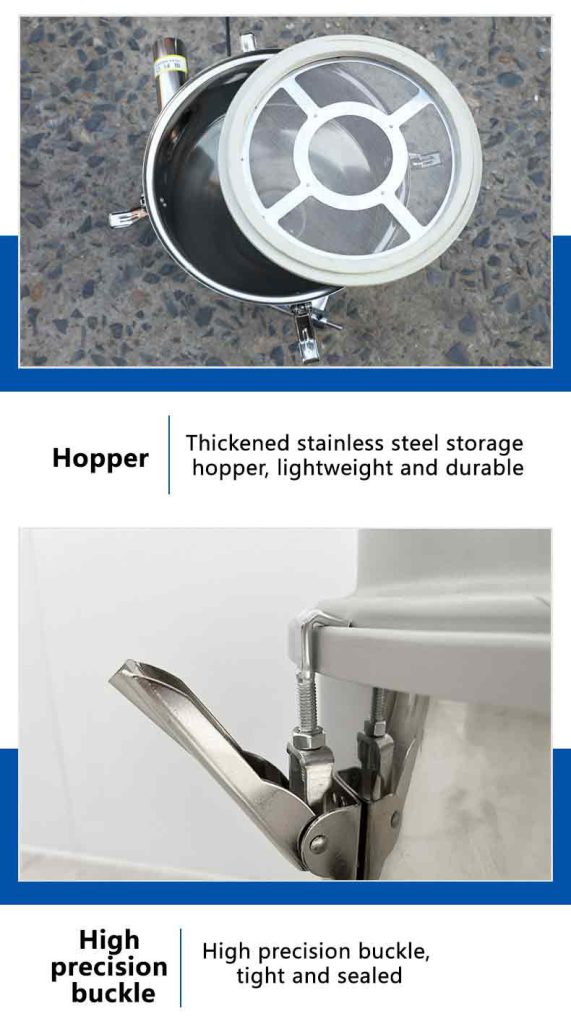

Stainless steel hopper, wear-resistant: The surface is beautiful, clean, bright, long-lasting, scratch free, never rusts, never breaks.

Powder vacuum suction machines are widely used for conveying raw materials in injection molding, and can automatically feed materials to injection molding machines.

Strong long-distance conveying capacity, stable production, reliable operation, and auxiliary equipment for fully automated production.

Easy maintenance, low noise, long service life, and equipped with a reverse dehumidification device.

The powder vacuum suction machine is equipped with a Japanese high-speed rectifier motor, which is light in weight, strong in suction, easy to install, and suitable for conveying new materials.

Parameters of Integrated Suction Machine

| Model | X300G | TLB-X400G | TLB-X750G | TLB-X850G | TLB-X850G | TLB-X900G | TLB-X900G | TLB-X900G | TLB-X900G | TLB-X900G | TLB-X900G | |

| Type | Carbon brush | Induction | Carbon brush | Induction | Induction | Induction | Induction | Induction | Induction | Induction | Induction | |

| Power (KW) | 1.12 | 0.75 | 1.12 | 1.1 | 1.5 | 2.2 | 3 | 4 | 5.5 | 7.5 | 11 | |

| Transmission capacity (kg/h) | 300 | 330 | 310 | 300 | 300 | 400 | 500 | 550 | 800 | 900 | 1300 | |

| Lift (M) | 3.5 | 4 | 4 | 4 | 5 | 4 | 4 | 5 | 5 | 5 | 5 | |

| Capacity (L) | 7.5 | 12 | 7.5 | 10 | 12 | 12 | 24 | 12 | 24 | 51 | 51 | |

| Pipe diameter (Φmm) | 38 | 38 | 38 | 38 | 38 | 38 | 38 | 38 | 50 | 50 | 50 | |

| Size | L/mm | 340 | 450 | 370 | 420 | 500 | 510 | 510 | 540 | 540 | 580 | 580 |

| W/mm | 340 | 370 | 300 | 380 | 400 | 370 | 370 | 560 | 560 | 600 | 600 | |

| H/mm | 590 | 660 | 560 | 640 | 720 | 670 | 670 | 1230 | 1230 | 1600 | 1600 | |

| Weight (kg) | 12 | 27 | 20 | 57 | 76 | 55 | 58 | 66 | 89 | 89 | 101 | |