- Home

- Products

- Dry Feeding Series

- Dehumidifier

Product Categories

Dehumidifier

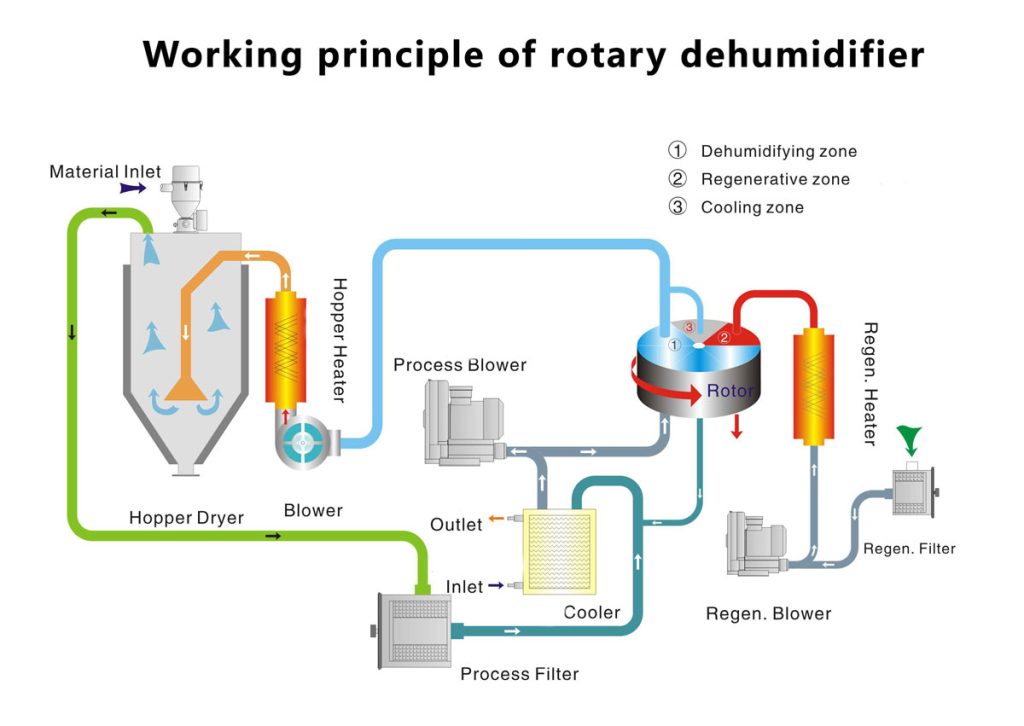

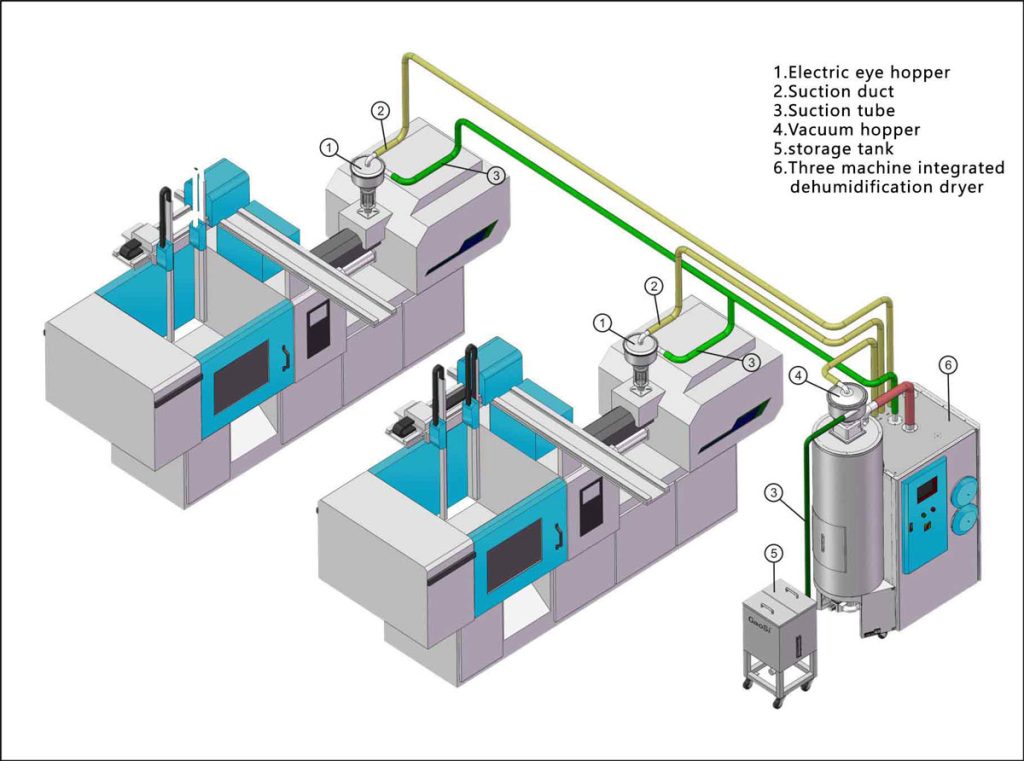

product description

Product features

Uniform distribution of hot air: Adopting a high-performance hot air diffusion device that evenly disperses hot air, maintaining uniform plastic drying temperature, increasing drying efficiency, and shortening drying time.

Reliability design: The equipment has a beautiful and sturdy appearance, convenient installation, multiple safety devices, and ensures work safety.

Dual overheating protection device: can reduce accidents caused by human or mechanical failures.

Refusing to burn and agglomerate, exceeding the preset temperature by 15 ℃, beeping alarm.

Intelligent temperature control: Adopting high-precision temperature regulators that can only control temperature, utilizing a ratio based deviation index thermometer to eliminate temperature errors. Set temperature and actual temperature dual display overtemperature alarm device to ensure safe operation. 24-hour automatic operation timing setting and fault automatic display function, plastic drying temperature rise (80-130) degrees.

Parameters of Dehumidifier

| Model | TLB-10L | TLB-15L | TLB-25L | TLB-50L | TLB-75L | TLB-100L | TLB-150L | TLB-200L | TLB-250L | TLB-300L | |

| Drying hopper | (L) Hopper Capacity | 18 | 29 | 44 | 90 | 125 | 175 | 250 | 350 | 425 | 500 |

| (KG) Hopper Capacity | 10 | 15 | 25 | 50 | 75 | 100 | 150 | 200 | 250 | 300 | |

| Drying system | (KW) Drying heater power | 1.2 | 2.1 | 2.1 | 4 | 4 | 5 | 5 | 9.1 | 15 | 15 |

| (KW) Drying blower power | 0.22 | 0.38 | 0.38 | 0.9 | 0.9 | 1.5 | 1.5 | 2.2 | 1.5 | 1.5 | |

| (℃) Drying temperature | 7~180 | 7~180 | 7~180 | 7~180 | 7~180 | 7~180 | 7~180 | 7~180 | 7~180 | 7~180 | |

| Dehumidification system | (KW) Regen heater power | 1.2 | 1.71 | 1.71 | 2.4 | 2.4 | 3.1 | 3.1 | 7 | 10.9 | 10.9 |

| (KW) Regen blower power | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.4 | 0.4 | 0.4 | |

| Average dew point of dry air | -40 | -40 | -40 | -40 | -40 | -40 | -40 | -40 | -40 | -40 | |

| Feed system | (KW) Feeding blower power | 1.1 | 1.1 | 1.1 | 1.1 | 1.1 | 1.1 | 1.1 | 3 | 3 | 3 |

| (L) Hopper capacity | 3 | 3 | 3 | 7.5 | 7.5 | 7.5 | 7.5 | 12 | 12 | 12 | |

| Size | L | 960 | 960 | 960 | 1158 | 1158 | 1285 | 1285 | 1450 | 1710 | 1710 |

| W | 960 | 960 | 960 | 639 | 639 | 639 | 639 | 740 | 900 | 900 | |

| H | 1326 | 1334 | 1584 | 1550 | 1850 | 1733 | 2123 | 2036 | 1887 | 2037 | |

| Weight | 200 | 224 | 233 | 299 | 309 | 331 | 346 | 500 | 685 | 700 | |